In laboratory settings, the choice of 50ml centrifuge tubes can greatly impact results. Selecting the right tubes is crucial for effective sample processing. According to a recent industry report by LabTech Insights, up to 30% of centrifuge-related errors stem from improper tube selection. This statistic highlights the importance of making informed choices when it comes to 50ml centrifuge tubes.

Dr. Emily Chen, a noted expert in laboratory equipment, states, "Using high-quality centrifuge tubes is essential for reliable experimental outcomes." Her experience emphasizes that not all 50ml centrifuge tubes are created equal. Factors like material, durability, and compatibility with spinning speeds play significant roles. Inadequate tubes can lead to leaks or sample contamination, issues that can prove costly.

Lab managers must consider specifics while shopping. Evaluate the tubes' tolerance for temperature and chemicals. Additionally, pay attention to the lid design; inadequate sealing may result in sample loss. Careful consideration of these factors often reveals that not all products on the market meet the rigorous needs of a laboratory environment. The pursuit of perfection in selection ensures better quality and fewer mistakes in research outcomes.

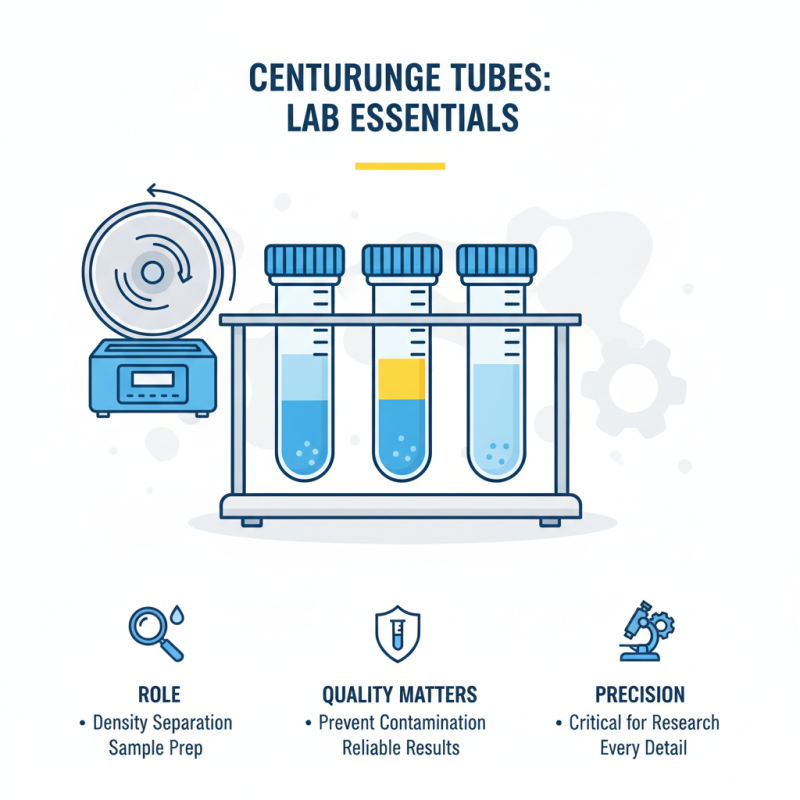

Centrifuge tubes play a critical role in laboratory procedures. They are essential for separating substances based on density. In experiments, the right type of tube can make a significant difference. Using a subpar tube can lead to contamination or compromised results. Every detail matters in precise applications, especially in research.

When choosing centrifuge tubes, consider the material. Some are made from plastic, while others are glass. Plastic tubes are generally lighter and less prone to breakage. Glass tubes can provide better clarity and chemical resistance. The size also varies. It's important to select the appropriate volume to match the experiment’s needs. A 50ml centrifuge tube is a common choice for many applications, offering sufficient space.

Lab managers often overlook minor details. This can result in wasted resources or unreliable data. Keep an inventory of your tubes. Regularly check for cracks or wear. Remember, the cheapest option might not always be the best choice. Balance cost with quality for reliable, repeatable results. Every lab should strive for high standards, even when it comes to the smallest tools.

When selecting 50ml centrifuge tubes, consider the material. Common choices include polypropylene and polycarbonate. Polypropylene is lightweight and resistant to chemicals. Polycarbonate offers clarity, which may be helpful for visibility. But remember, each material has its limitations. Sometimes, clarity doesn’t mean safety.

Next, the tube cap design is crucial. Some tubes have snap-on lids, while others use screw caps. Snap-on lids may be easier to use, but they can leak. Screw caps typically offer better sealing but demand more time to open and close. Think about your workflow. Are you in a hurry?

Finally, check for graduations on the tubes. Clear markings can streamline your procedures. It helps avoid guesswork when measuring solutions. However, some tubes fade with time. You might not realize this until it’s too late. Testing different brands might be necessary to find the right fit. It’s a task that requires careful thought and perhaps even some trial and error.

When selecting centrifuge tubes, the material significantly influences performance. Common materials include polypropylene, polystyrene, and polycarbonate. Each has distinct properties making them suitable for different applications. For instance, polypropylene is known for its chemical resistance and durability. According to a study published in the Journal of Materials Science, polypropylene can withstand temperatures up to 121°C, making it ideal for autoclaving.

On the other hand, polystyrene offers superior optical clarity. This is useful for applications requiring visibility of the sample. However, it has lower chemical resistance compared to polypropylene. A report from Biopharma Research suggests that polystyrene tubes are more prone to breakage under high-stress conditions. Polycarbonate, while being stronger, is not as chemically resistant as polypropylene. Thus, it might not be ideal for all laboratory conditions.

It's crucial to consider your specific needs. A material that works for one experiment may falter in another due to its limitations. Frequent assessments of tube performance are necessary to ensure reliable results. Ultimately, an understanding of how tube materials interact with your samples will guide you toward making informed decisions.

Choosing the right 50ml centrifuge tubes is crucial for any lab. Evaluating brands based on industry standards helps ensure reliability. A recent report from the American Society for Testing and Materials noted that materials used in centrifuge tubes must withstand forces over 10,000 RCF. Tubes need to be clear and free from defects to allow for accurate sample observation.

Reviewing user feedback adds value. Many lab technicians emphasize the importance of consistent wall thickness and proper sealing. Tubes that do not meet these criteria can lead to sample contamination or loss. According to surveys, 30% of users have reported issues with leakage in cheaper brands.

Tip: Always check for certifications. Look for tubes that comply with ISO or ASTM standards. Such certifications often indicate higher quality. It may seem convenient to buy cheaper products, but this could lead to costly mistakes. Remember, not all products are created equal.

Consider performing a stress test on new tubes before regular use. This practice can reveal weaknesses not apparent during initial inspection. User experience can vary greatly based on environment and handling. Pay attention to feedback from peers in your field. Engage with reviews that detail real-world application instead of marketing claims.

Storing and handling 50ml centrifuge tubes requires careful attention. Keep these tubes upright in a designated storage area. A consistent temperature is essential. Extreme temperatures can affect sample integrity. Avoid exposing the tubes to direct sunlight or excessive heat.

Labeling is crucial. Use clear and durable labels to identify samples. This prevents mix-ups during experiments. Consider a labeling system that includes dates and contents. When handling, inspect each tube for damage. Cracks or leaks can compromise your samples. Handle tubes gently to prevent accidental breakage.

Cleaning is another important practice. Use appropriate detergents for decontamination. If reuse is planned, ensure thorough cleaning. Some residues can interfere with results. Regularly review storage practices for efficiency. Reflect on your methods. Continuous improvement enhances lab safety and sample reliability.

| Feature | Description | Best Practice |

|---|---|---|

| Material | Commonly made from polypropylene or polystyrene. | Choose polypropylene for heat-resistant applications. |

| Capacity | Typically designed to hold 50 ml of liquid. | Ensure not to exceed the maximum capacity to avoid spills. |

| Closure Type | Screw cap or snap cap options available. | Use screw caps for better seal during centrifugation. |

| Autoclavable | Some tubes are autoclavable to ensure sterilization. | Check if the package indicates autoclavability. |

| Graduation Marks | Many tubes have graduated markings for easy measurement. | Select tubes with clear markings for precision. |

| Color Coding | Some tubes come in various colors for easy identification. | Use color-coded tubes to enhance laboratory organization. |

| Centrifugation Speed | Tubes are rated for different maximum speeds. | Always check the maximum speed rating before use. |

| Storage Conditions | Store in a cool, dry environment away from direct sunlight. | Label and date storage to monitor usability. |